Power Products & Services

HOME / EMD / Markets & Products / Power Products & Services

Power Products & Services

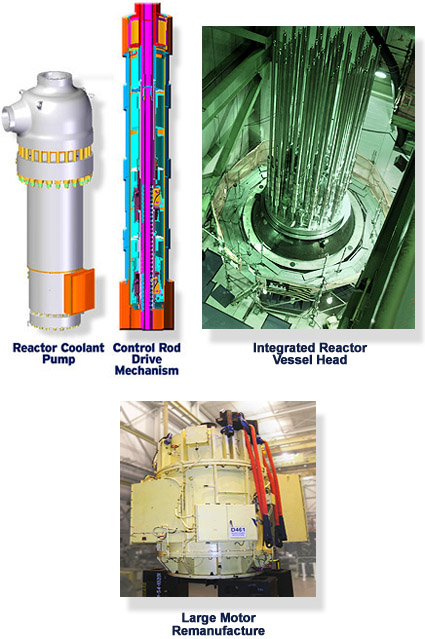

EMD is an integrated supplier of advanced, critical function motors, drive mechanisms, and pumps to the nuclear power industry. Established in the early 1950s, EMD was the first privately owned facility dedicated to the manufacture of nuclear components. EMD systems are specified when high reliability, shock resistance, long life expectancy, low maintenance, and harsh environment operation are required. EMD offers products and engineered services for reactor coolant pumps, control rod drive mechanisms as well as a broad range of engineered services for all reactors across the globe whether they are new, existing or re-starts.

Commercial Nuclear Products

- Reactor Coolant Pumps

- Control Rod Drive Mechanisms

- Integrated Reactor Vessel Head

- Large Motor Remanufacture

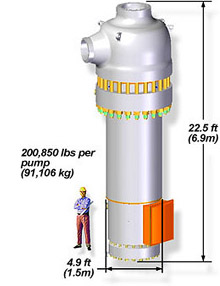

Reactor Coolant Pumps

EMD’s advanced pump technology is being used for Generation III+ nuclear power plants, the Westinghouse AP1000 reactor plant, and the next generation of nuclear plants in China.

EMD uses a proven design philosophy to ensure highly reliable, long life designs incorporating:

- Metallic cans protect the motor rotor and stator from the operating fluid

- No shaft seals

- Water lubricated bearings operating with no wear

- Additional features

- Up to 60 year life with no maintenance

- Flywheels to provide the inertia based on plant coast-down requirements

- Additional features

In addition to our advanced canned motor RCP, EMD has manufactured and delivered over 350 shaft seal reactor coolant pumps and Motors to operating commercial power plants around the world.

Control Rod Drive Mechanisms

Control Rod Drive Mechanisms (CRDMs) are utilized to control the level of activity in the reactor core. EMD has over 45 years of design and manufacturing experience with CRDMs. There are more than 5,000 CRDMs operating in 88 plants worldwide that we designed and manufactured. Our latest design is qualified for 7 million steps and 40 years of operation. We have over 50 years of successful operation with operating availability greater than 99.9%

Integrated Reactor Vessel Head

EMD delivered, ahead of schedule, the first U.S. supplied Integrated Reactor Vessel Head with 55 CRDMs to Texas Utility's Comanche Peak Site in 2006.

Critical aspects

- Regulate the level of radioactivity in the reactor vessel by insertion or withdrawal to increase or decrease absorption rate of atomic particles

- Proven reliable designs - over 40 years of successful operation

- Operating availability > 99.9%

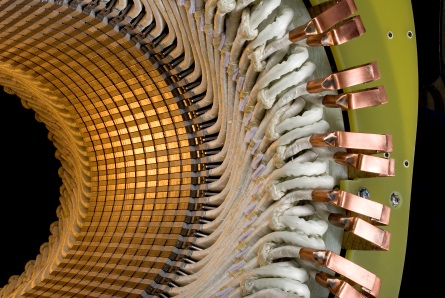

Large Motor Remanufacture

Extending the life of critical performance equipment

EMD has extensive experience and resources in large motor remanufacture. Our design and analysis will extend and even enhance the life of high-end equipment through careful design and analysis. State-of-the-art manufacturing and assembly is carefully coupled with thorough testing for all large motor remanufacture and refurbishment.

Services provided:

- Design

- Analysis

- Manufacture

- Assembly

- Testing

Comprehensive motor remanufacture

- 191 Motors Remanufactured

- 41 Stator Rewinds

- 25 Years of Experience

- Equipment Designer

- Equipment Manufacturer

- Dedicated

- Remanufacturing Facility

- Personnel

- Test Facility

- U.S. NRC Licensed for Radioactive Material

- Receipt

- Storage

- Disposal

- Cleaning and Decontamination

- Condition Assessment

- Equipment Upgrades

- Stator Rewinding

- Shaft Repairs

- Coatings Application

- Certifications:

- ISO 9001

- ASME N and NPT Stamps

- 10CFR50 Appendix B

For more details please Contact Us